All kinds of electrical wiring throughout your home meets in the circuit breaker box, leaving a lot of room for all unwanted streams of air to flow into your living space.

These channels can be also utilized by bugs and other animals to get into unwanted areas.

And if a fire breaks out, the air inflow may help fuel the flames and smoke, spreading them all over the place.

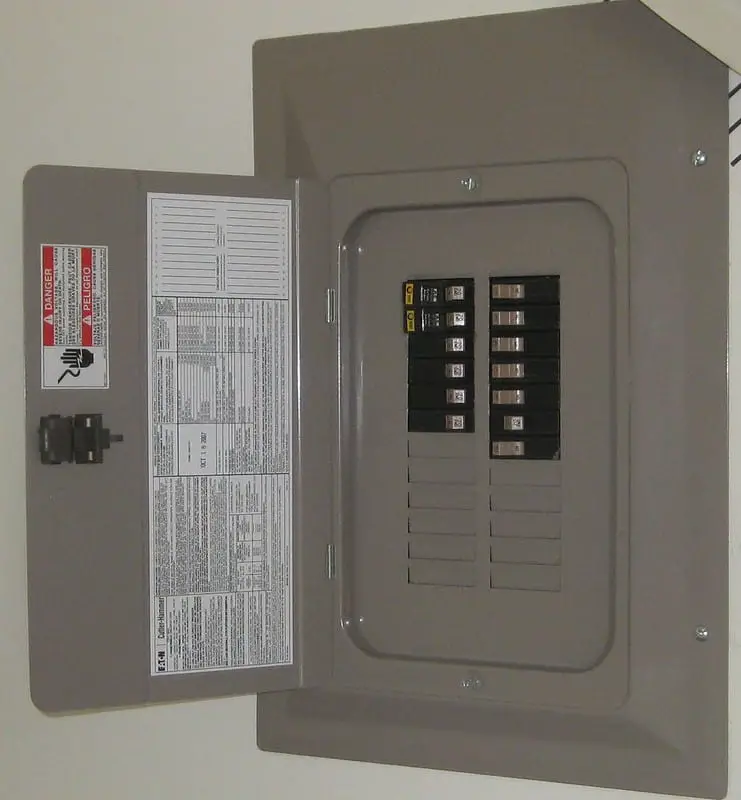

Can You Put Insulation Around A Circuit Breaker Box?

Absolutely yes, especially if you are looking to stop energy loss through it. If you examine your electrical box more closely – more so a box located on the exterior wall or one installed to face unheated spaces – you will most feel cold drafts of cold air coming through it or around the corners and edges of the cover plate. And although you may miss it depending on the season, the box is also a spot where you’re losing your precious air-conditioned and clean air to the outside during hot seasons.

The Three Methods Of Insulating A Circuit Breaker Panel

The process of insulating your electrical box might the easiest project you will ever undertake.

It only involves adding the foam insulation material in all areas you deem necessary and then sealing any air gaps you could find around the box.

There are 3 common methods for it.

- the rigid foam method

- the spray foam method

- sealing gaps.

1. Using A Rigid Foam to Insulate Your Box

Tools

- Utility knife or awl

- Screwdriver

Materials

- A container with rigid foam insulation

- Fiberglass insulation (if you really need it)

- Caulk or duct tape (if necessary, also)

Procedure

First off, find out whether you can access the backside of your electrical box.

If you can, take a piece of your rigid foam insulator and slip it between the wall and the box.

This is more effective than simply stuffing fiberglass insulation material behind the electrical box because compressing fiberglass dramatically cuts its insulating value, something that may render it useless.

- Start by clearing away any debris or old insulation materials from behind your electrical box.

- Chop a piece of your rigid foam insulation material, just the right size to fit in-between the wall studs.

- Smoothen the edges of the piece and place it into the space. Hold it in position if necessary – you can use caulk, foil duct tape, or any other suitable adhesive.

- Complete it by insulating around the bottom, top, and side of the electrical box with your fiberglass insulation or more rigid foam notched to fit snuggly around the box. Avoid compressing the fiberglass insulation just to accommodate the electrical box.

2. How to Insulate an Electrical Box with Spray Foam

Tools

- Utility knife or awl

- Screwdriver

Materials

- A can with spray foam insulation

Procedure

Where there’s no insulation material between the rear of your circuit breaker box and the exterior wall, you might want to add a layer of insulation behind it.

The first and most practical solution is to take spray foam, like Great Stuff.

If there’s plenty of room around your box, you may spray the foam behind it to fill any gap between it and the outside wall surface.

We suggest a low-expanding foam because it fills midsized and small gaps uniformly without the need to apply undue force to surrounding materials.

One major benefit of foam is its ability to air-seal and insulate at the same time, so you end up solving two problems at once, with one product.

Watch out – do not press the foam all the way into the box! Also, never spray your insulating foam inside the electrical box. If you do, the wires may overheat and even cause fires.

Proceed like this:

- Remove the screw(s) off the electrical box’s cover plate. Now pull off the loose cover plate.

- Take a few minutes to inspect the exterior edges of your box.

- More often than not, there are few gaps around these edges that you can utilize to insert the elongated straw (applicator straw) protruding from the spray can.

- In absence of these gaps, you can settle on making a few tiny holes with an awl or your average utility knife.

- Again, be watchful to never push your tools too deep in the wall material (utmost 1/2”) so that your tools don’t end up getting into contact with underlying electrical wires.

- Proceed to insert the dry and clean applicator straw into every hole or gap and keep sliding it in until you hit beyond the rear of the electrical box.

- Make a few sprays behind the box

- Proceed to repeat this at all 4 sides of your box, if possible.

3. Seal The Gaps in The Electrical Box Method

Tools

- Utility knife

- Screwdriver

Materials

- Exterior sealant or caulk

- Neoprene foams outlet gasket

- Fiberglass solution or low-expansion spray foam

Procedure

Alternatively, you can greatly reduce the extent of heat loss by sealing the air gaps dotting around your box or any pipes or cables entering through exterior walls.

In some cases, wall boxes are set up back to back thus creating a throughway to the outdoors.

Here is how to insulate the gaps:

- Stop the airflow by sealing all the gaps from the exterior of the home using any exterior-grade caulk or exterior sealant.

- Exterior products are recommended because they stand up to weather insults, including sunlight, better than any standard (interior) formulas.

- You will also fall in love with the tight seal they will create.

- Seal the box from inside the home by removing all the cover plates on outlets and switches and looking for the presence of air gaps around your box where you can easily feel air flowing from outside.

- Plug any gaps around the box with low-expansion spray foam or loose insulation. Leave the spray foam to harden for a few minutes, then trim the excess overflows with your utility knife.

- Lastly, install your neoprene insulating foam gasket over the box, behind the cover plate.

- The gasket will come with cutouts for the switches or receptacles.

- Once the cover plate has been reinstalled, the gasket will form a tight seal on the perimeter of the entire opening.

- There’s an extra advantage to this installation: the foam gasket will deaden the sound transmission.

How To Safeguard Against Fire

The 3 methods above are used to insulate the electrical box and prevent the cold from flowing into the home through it.

But, what if the fire is your main concern?

If a fire starts in the box or anywhere close to it, you want it to stay outdoors.

There are several ways to insulate and prevent fires from spreading indoors through the gaps and holes in the box.

Dow GREAT STUFF™ Fireblock Foam Sealant

Dow GREAT STUFF™ Fireblock Foam Sealant is one of the most often used materials when it comes to sealing pipes, cables, and duct penetrations to minimize airflow.

During home fires, smoky flames, toxic fumes from burning plastics, and other types of harmful gasses can spread quickly through the tiny gaps in your electrical box, but not past this foam.

It could help you conserves energy as well because it reduces drafts, permitting you to cut on cooling.

However, this should be your alternative fire blocking material after you have considered all other fire insulation materials you could add in or on your electrical box.

Dow GREAT STUFF PRO™ Gaps and Cracks Sealant

Even better, you can opt for Dow GREAT STUFF PRO™ Gaps and Cracks Sealant which can also be used to cover larger more profound cracks that may be present on the edges of your box.

This sealant is only used when things are so bad, with larger holes gaping close to the box or anywhere on the wall.

Never apply these foam sealants into the electrical panel.

In A Nutshell

So, can you put insulation around a circuit breaker box?

Yes. It is especially necessary if you want to stop energy loss through it.

If you examine your electrical box more closely – more so a box located on the exterior wall or one installed to face unheated spaces – you will most feel cold drafts of cold air coming through it or around the corners and edges of the cover plate.

And although you may miss it depending on the season, the box is also a spot where you’re losing your precious air-conditioned and clean air to the outside during hot seasons.

There are 3 common methods to achieving it: the spray foam method, the rigid foam method, and sealing gaps.

If a fire starts in the box or anywhere close to it, you want it to stay outdoors.

There are several ways to insulate and prevent fires from spreading indoors through the gaps and holes in the box. You can use one of the two popular foam sealants from DuPont.

These foams could help you conserves energy as well because it reduces drafts, permitting you to cut on cooling.

Some foams will insulate the box and also dampen the sound from the outside. Some foams should not be sprayed directly into the box.